- Obecnie brak na stanie

Motor with 64 CPR Encoder for 37D mm Metal Gearmotors (No Gearbox)

darmowa wysyłka na terenie Polski dla wszystkich zamówień powyżej 500 PLN

Jeśli Twoja wpłata zostanie zaksięgowana na naszym koncie do godz. 11:00

Każdy konsument może zwrócić zakupiony towar w ciągu 14 dni bez zbędnych pytań

Motor with 64 CPR Encoder for 37D mm Metal Gearmotors (No Gearbox)

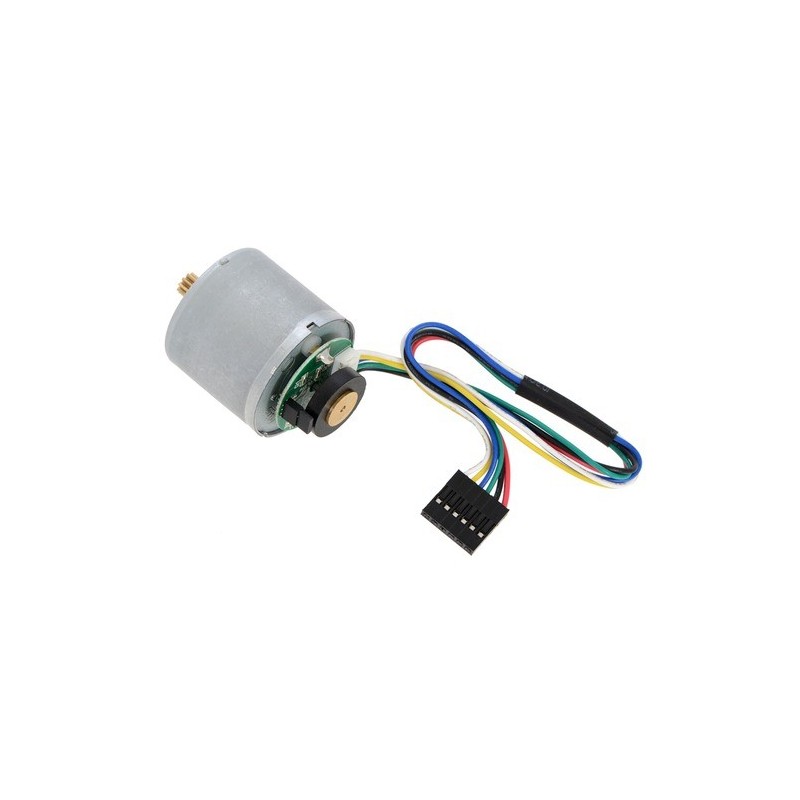

This is the motor and encoder portion of our 37D mm metal gearmotors with 64 CPR encoders. It does not include a gearbox, but the pinion gear on the output shaft works with all of our 37D mm gearmotor gearboxes, so this can be used as a replacement motor or encoder for those gearboxes. It is intended for use at 12 V, though the motor can begin rotating at voltages as low as 1 V.

Key specs at 12 V: 11,000 RPM and 300 mA free-run, 5 oz-in (0.3 kg-cm) and 5 A stall.

|

This motor with integrated 64 CPR (counts per revolution) quadrature encoder is intended as a replacement motor and encoder for our 37D mm metal gearmotors. The 2mm output shaft has a non-removable pinion gear that works with all of our 37D mm gearmotor gearboxes. Note that we do not sell the 37D mm gearboxes separately, but if you have a gearmotor with a damaged motor or encoder (or if you want to effectively add an encoder to a version without an encoder), you can transfer the gearbox to this replacement motor.

The motor has a diameter of 34.5 mm (1.36 in) and a length of approximately 44 mm (1.7 in) from the top of the motor can to the bottom of the encoder. The top of the motor has six mounting holes evenly spaced around the outer edge threaded for M2.5 screws. These mounting holes form a regular hexagon, with the center of each hole located 13 mm from the center of the output shaft.. The mounting holes have a depth of approximately 3.5 mm.

You will typically want to combine this motor with a gearbox to give it a more appropriate combination of torque and speed (without a gearbox, it offers very high speed with very low torque). Our 37D mm line of metal gearmotors consist of this motor combined with different gearboxes. We do not carry the gearboxes by themselves, so unless you are looking at this as a replacement motor for a compatible gearbox you already have, we strongly recommend you consider getting a preassembled gearmotor with the gear ratio that best suits your project requirements.

| Gear Ratio | No-Load Speed @ 12 V | Stall Torque @ 12 V | Stall Current @ 12 V |  With Encoder |  Without Encoder |

|---|---|---|---|---|---|

| 1:1 | 11,000 RPM | 5 oz-in | 5 A | motor without gearbox | |

| 19:1 | 500 RPM | 84 oz-in | 5 A | 37Dx52L mm | 37Dx52L mm |

| 29:1 | 350 RPM | 110 oz-in | 5 A | 37Dx52L mm | 37Dx52L mm |

| 50:1 | 200 RPM | 170 oz-in | 5 A | 37Dx54L mm | 37Dx54L mm |

| 67:1 | 150 RPM | 200 oz-in | 5 A | 37Dx54L mm | 37Dx54L mm |

| 100:1 | 100 RPM | 220 oz-in | 5 A | 37Dx57L mm | 37Dx57L mm |

| 131:1 | 80 RPM | 250 oz-in | 5 A | 37Dx57L mm | 37Dx57L mm |

These motors are intended for use at 12 V, though the motor can begin rotating at voltages as low as 1 V.

|

| 37D mm metal gearmotor with 64 CPR encoder. |

|---|

A two-channel Hall effect encoder is used to sense the rotation of a magnetic disk on a rear protrusion of the motor shaft. The quadrature encoder provides a resolution of 64 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output, multiply the gear ratio by 64. The motor/encoder has six color-coded, 11" (28 cm) leads terminated by a 1×6 female header with a 0.1" pitch, as shown in the main product picture. This header works with standard 0.1" male headers and our male jumper and precrimped wires. If this header is not convenient for your application, you can pull the crimped wires out of the header or cut the header off. The following table describes the wire functions:

| Color | Function |

|---|---|

| Red | motor power (connects to one motor terminal) |

| Black | motor power (connects to the other motor terminal) |

| Green | encoder GND |

| Blue | encoder Vcc (3.5 – 20 V) |

| Yellow | encoder A output |

| White | encoder B output |

The Hall sensor requires an input voltage, Vcc, between 3.5 and 20 V and draws a maximum of 10 mA. The A and B outputs are square waves from 0 V to Vcc approximately 90° out of phase. The frequency of the transitions tells you the speed of the motor, and the order of the transitions tells you the direction. The following oscilloscope capture shows the A and B (yellow and white) encoder outputs using a motor voltage of 12 V and a Hall sensor Vcc of 5 V:

|

| Encoder A and B outputs for 37D mm metal gearmotor with 64 CPR encoder (motor running at 12 V). |

|---|

By counting both the rising and falling edges of both the A and B outputs, it is possible to get 64 counts per revolution of the motor shaft. Using just a single edge of one channel results in 16 counts per revolution of the motor shaft, so the frequency of the A output in the above oscilloscope capture is 16 times the motor rotation frequency.

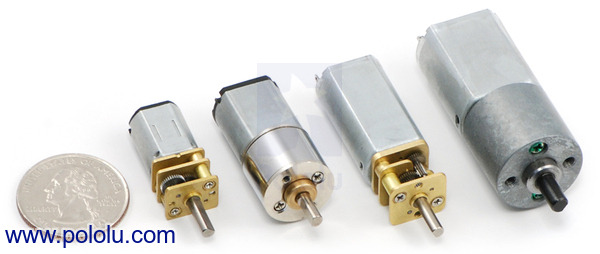

We offer a wide selection of metal gearmotors that offer different combinations of speed and torque. Our metal gearmotor comparison table can help you find the motor that best meets your project’s requirements.

|

| Some of the Pololu metal gearmotors. |

|---|

HK 10x4.5 SF Props 2pc CW 2 pc CCW Rotation (Blue) (25819)

Brak towaru

Brak towaru

BeagleBone AI to minikomputer z procesorem AM5729, do jego dyspozycji jest 1 GB pamięci RAM DDR3L. Został stworzony w celu poznawania zagadnień związanych ze sztuczną inteligencją. BBBONE-AI

Brak towaru

Brak towaru

Rechargeable NiMH Battery Pack: 6.0 V, 200 mAh, 3+2 1/3-AAA Cells, JR Connector

Brak towaru

Brak towaru

Moduł radiowy XBee (ZigBee) firmy Digi o mocy wyjściowej 63 mW (+18 dBm), szybkości do 250 kb/s i zasięgu transmisji do 3200 metrów. Moduł wyposażono w 4 10-bitowe wejścia ADC oraz 15 linii GPIO. Transmisja może być szyfrowana za pomocą AES-128.

Brak towaru

Brak towaru

Brak towaru

Brak towaru

Płytka z modułem WiFi i Bluetooth LE Espressif ESP32-S3-WROOM-1. Oferuje 8 MB pamięci Flash i 8 MB PSRAM. Espressif Systems ESP32-S3-DevKitC-1-N8R8

Brak towaru

Brak towaru

Brak towaru

Brak towaru

Brak towaru

Brak towaru

Motor with 64 CPR Encoder for 37D mm Metal Gearmotors (No Gearbox)